Specifying sustainable floor coverings usually requires evaluating multiple product attributes. This typically involves scrutinising materials for recycled content, material health and embodied carbon as well as checks on how responsibly a product has been manufactured. Progress made by manufacturers in all these areas has already helped to drive down carbon emissions in buildings. When it comes to disposal of used flooring however, how can this contribute?

As one of the main flooring types specified commercially, carpet tiles already have well established recycling streams. At present, these largely included the deconstruction of material content to make other downstream products, such as nylon automotive components or incineration for waste to energy recovery. While these options succeed in diverting carpet from landfill, a fully circular approach, where carpet tiles are re-used, offers an even more favourable option. This will become particularly important as the construction industry strives to achieve ambitious carbon emissions targets. It can also in help businesses improve their ESG performance.

(Learn more in our blog: EMBRACING THE CIRCULAR ECONOMY: HOW CARPET TILE RE-USE WORKS)

Moving from carpet tile recycling to carpet tile re-use

When carpet tiles in offices, public or educational building are no longer needed, they are very often not yet at the end of their useful life. High performance carpet tile products engineered for durability and longevity, such as Milliken’s cushion backed carpet tiles, offer extended wear performance. They have potential for an additional useful life beyond their initial installation and sometime beyond their wear warranty, which can already be up to 15 years.

By eliminating the re-processing stage required by ‘conventional recycling’ for a carpet tile to become another product or be converted into energy, it is possible to drive down the products’ lifetime carbon footprint even further by granting it a second life. Re-framing our thinking from ‘recycling’ to ‘re-use’ can drive down the embodied carbon in buildings and help make positive progress towards mitigating the climate crisis.

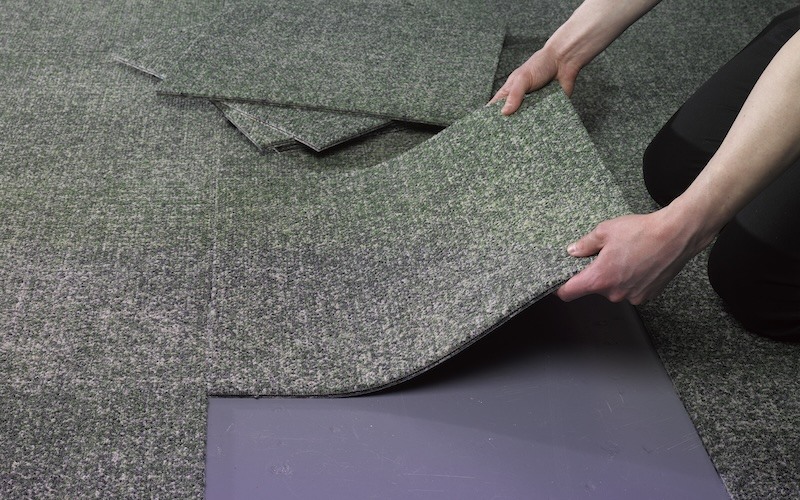

How easy is it to re-use carpet tiles?

For companies, opportunities to re-purpose carpet tiles will arise for a number of reasons. A building refurbishment, business restructuring, change of use or change of occupancy can all present a need to uplift and remove carpet. Where there is plenty of useful life still in the carpet, circularity programmes such as Milliken’s N/XT LIFE provides a dedicated infrastructure that includes flooring contractors with take-back specialists who uplift and remove carpet. Working alongside dedicated carpet re-use distribution partners they are able to facilitate the logistics of the process.

For large companies with multiple sites, carpet can potentially be re-installed in another area of the company’s own building stock. Or alternatively, donating used carpet, particularly when supporting social or community projects, can make an important contribution to a company’s ESG goals. Some manufacturers, including Milliken, are also now working with charities, such as the Salvation Army, with large distribution networks to channel donated carpet directly to where it is needed. Additionally partners such as Uplyfted work with social housing organisations in the UK to provide tenants with used flooring. This delivers important social value by helping to create quieter, warmer, more energy efficient homes to those need. Whether donating or re-using within their own building, with full traceability in place, some manufacturers will provide a ‘Certificate of Take Back’ to validate any re-use or donations.

Uplyfted carpet tile recycling

Uplyfted carpet tile recycling

How can you specify second-life carpet tiles?

For architects or designers looking to minimise the carbon impact of a new or refurbished building, specifying recycled carpet tiles through a circularity re-use programme can offer a realistic alternative to new. By 2030 zero embodied carpet will be targeted by SBTi, which means the construction industry will need to look beyond carbon offsetting to a product’s actual embodied carbon measure.

With this on the horizon, as carpet re-use infrastructures develop, there is already a growing inventory of zero-embodied carbon carpet tile products available to choose from. Carpet tile re-use specialists include companies such as Paris-based Orak and Re-Carpet in Sweden who specialise in supplying cleaned re-used carpet tiles. EPDs are provided that include transportation and the carpet also qualifies for LEED V4 re-use credits and BREEAM/ISO6001 certification.

How to specify new carpet tiles for future re-use

With carpet tile re-use set to become a familiar part of specification landscape, being aware a new carpet tile product’s ‘designed-in circularity’ when specifying is crucial to ensuring its potential for a successful second life. Here’s what to look out for:

Carpet tiles designed for disassembly

Carpet tiles that are firmly glued to the floor can be problematic to uplift. Specifying glue-free carpet tiles, will ensure the carpet tile and sub-floor is protected and will future-proof any requirement for them to be uplifted and re-used.

TractionBack® glue-free carpet tiles

TractionBack® glue-free carpet tilesHigh performance carpet tiles

A long wear warranties of 12 – 15 years, will provide a good indicator of the durability of a carpet and its potential for re-use. Carpet tiles with an integral, open-cell cushion backing are most likely to retain their appearance and performance for longer.

A reliable carpet tile take-back infrastructure

Choosing a manufacturer that already has a Carpet Tile Circularity Programme in place, will streamline the logistics of organising the process of uplift and re-use. Also read our blog: CARPET TILE RECYCLING: WHY GLUE-FREE INSTALLATION IS THE FUTURE

Not all carpet tiles can be re-used

Inevitably, there will be situations where carpet tiles are beyond a second life. In these cases, the current established recycling processes, outlined earlier in this blog, are still viable for ensuring safe disposal and avoidance of landfill.

As we continue to improve on operational efficiencies to create low-carbon buildings, embodied carbon will form an increasing proportion of a building’s overall lifetime carbon emissions. To meet our ambitious climate goals, addressing embodied carbon through commercial product re-use programmes have to become an integral part of the construction industry’s climate mitigation strategy.

Find out more in our GUIDE TO SPECIFYING LOW-CARBON CARPET TILES

Orak

Orak